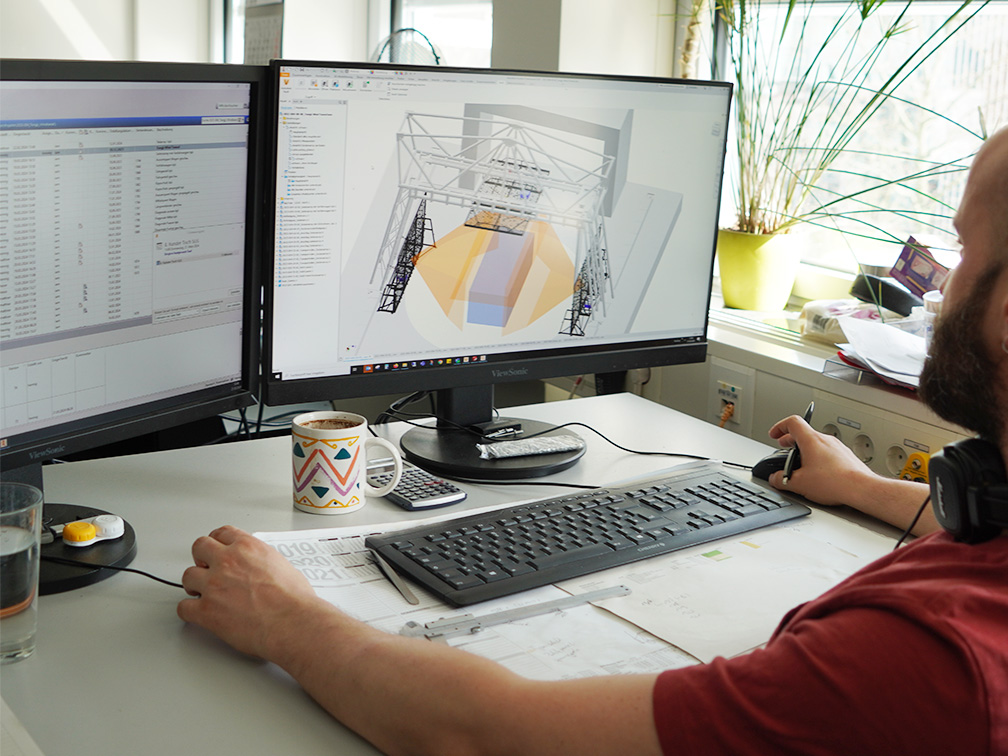

At the heart of the system lies a suite of advanced software, selected to meet the specific needs of Tongji-SAWTC.

Gfai's NoiseImage Controller empowers operators to oversee and manage the entire data acquisition process, including the smooth exchange of information with the model fitting system, while handling the storage of large volumes of data efficiently.

Once the data is acquired, which takes only a few seconds, it is processed and analyzed using our NoiseImage software and its specialized WindTunnel module. At this stage, utilizing gfai's advanced algorithms module for NoiseImage is essential for wind tunnel measurements, as it effectively addresses the challenge of localizing multiple noise sources, with distinct sound pressure levels, originating from various parts of the vehicle. This processing step can be performed outside the wind tunnel, allowing it to remain available for additional measurements. As the effective use of time in the wind tunnel is a critical aspect to be regarded, both the overall short-time measurement process and the possibility to post-process the data externally are indispensable.