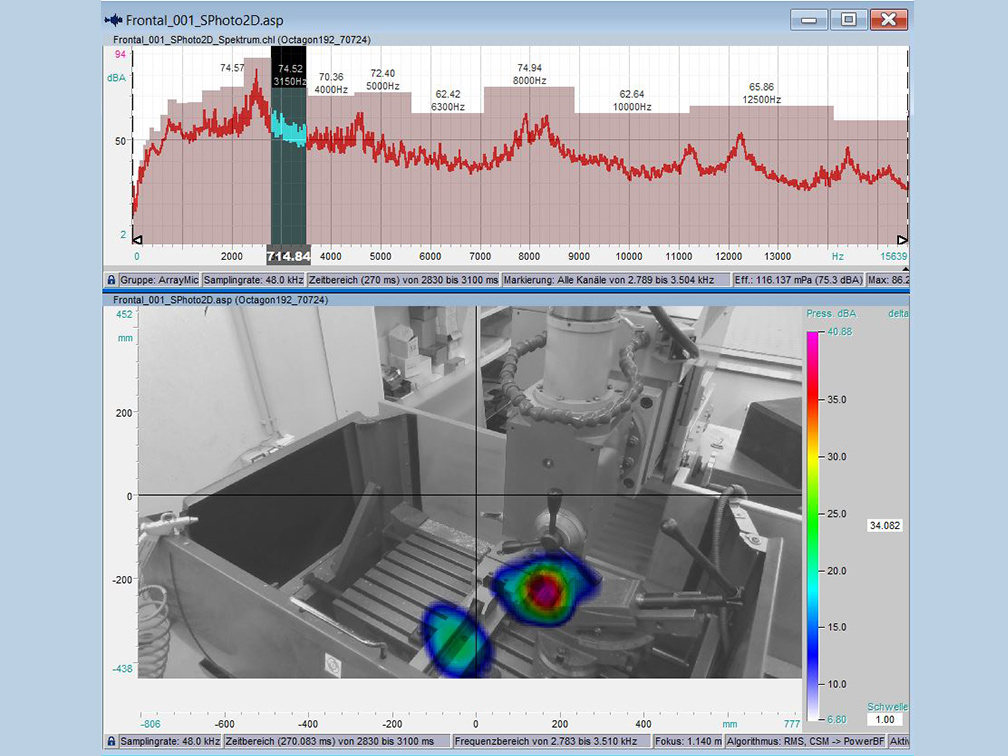

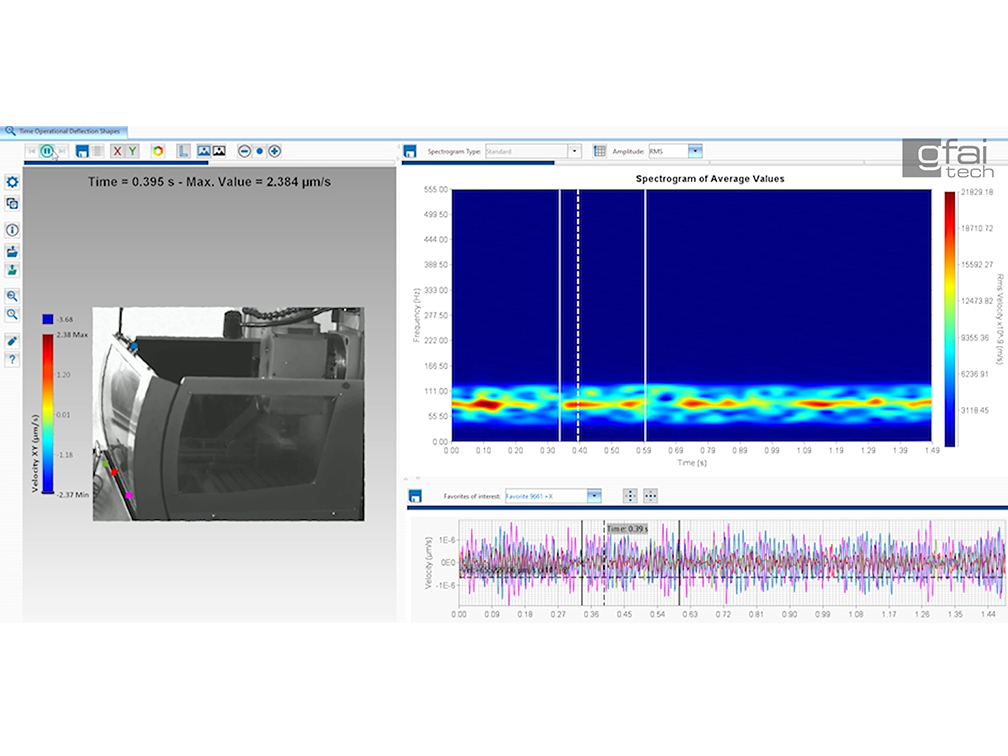

Ultrasound is one of the main indicators about Condition Monitoring, the Acoustic Camera can be your tool to finding defects that can lead to asset failure. Use the powerful results, going deep in the frequency analysis, applying advanced algorithms and filtering to save money in your industrial process. Even in rotational machine, don´t forget that you can add external sensors like tachometers to the gfai tech data recorder.

Visualize sound emissions like frictions, impacts, air leaks, or fluid flow inside tubes will help you to quickly identify costly energy waste.

Products related to energy generation can be analyzed by the Acoustic Camera from a different perspective too: Noise Reduction. If you know where your noise spot is and the related frequency range, it will be easier and more effective to develop useful solutions and develop quiet products and plant for examles electric transforms, compressors, wind turbines.