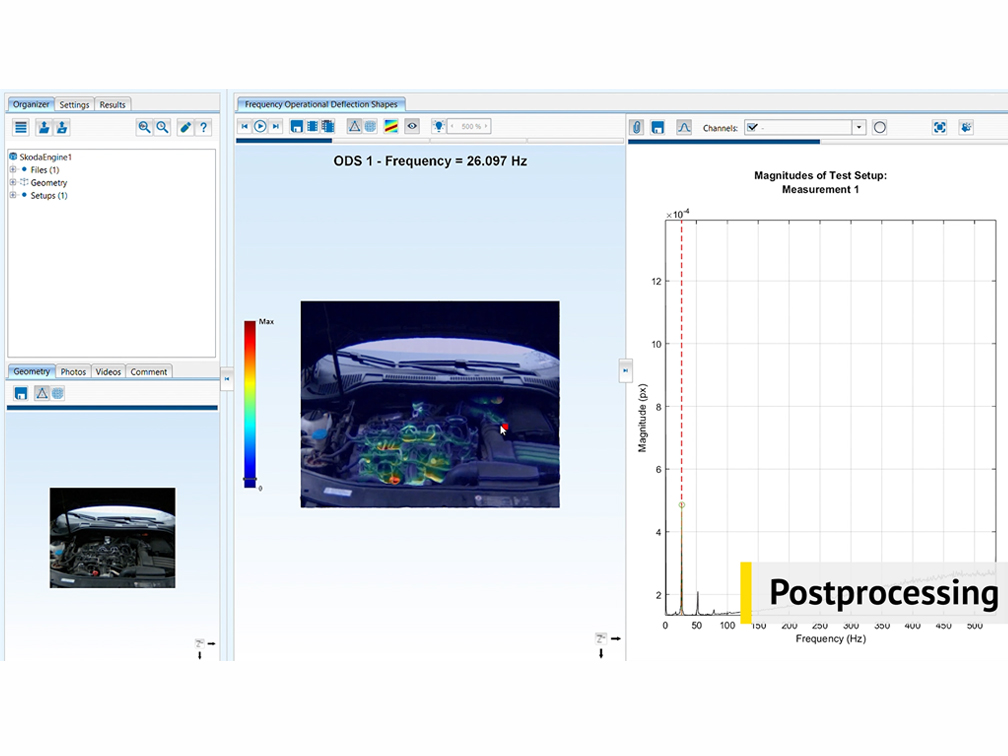

With WaveCam, our innovative vibration analysis software that combines high-resolution video recordings and motion amplification, you can precisely visualise and analyse vibrations on complex assemblies such as car engines.

NVH (noise, vibration, harshness) analysis plays a crucial role in the development and prototyping of powertrains. WaveCam enables engineers to analyse the oscillations and vibrations of motors and drive components both on the test bench and when installed. These insights help to better understand the behaviour of powertrains and make targeted improvements to performance, safety and comfort.

Whether for combustion engines or electric motors - the requirements for quality, safety and comfort are constantly increasing, particularly in the automotive sector. WaveCam supports engineers in meeting these requirements and optimising the performance of drive components.

Take a look at the video with the examples.