Hardware

The main hardware components include:

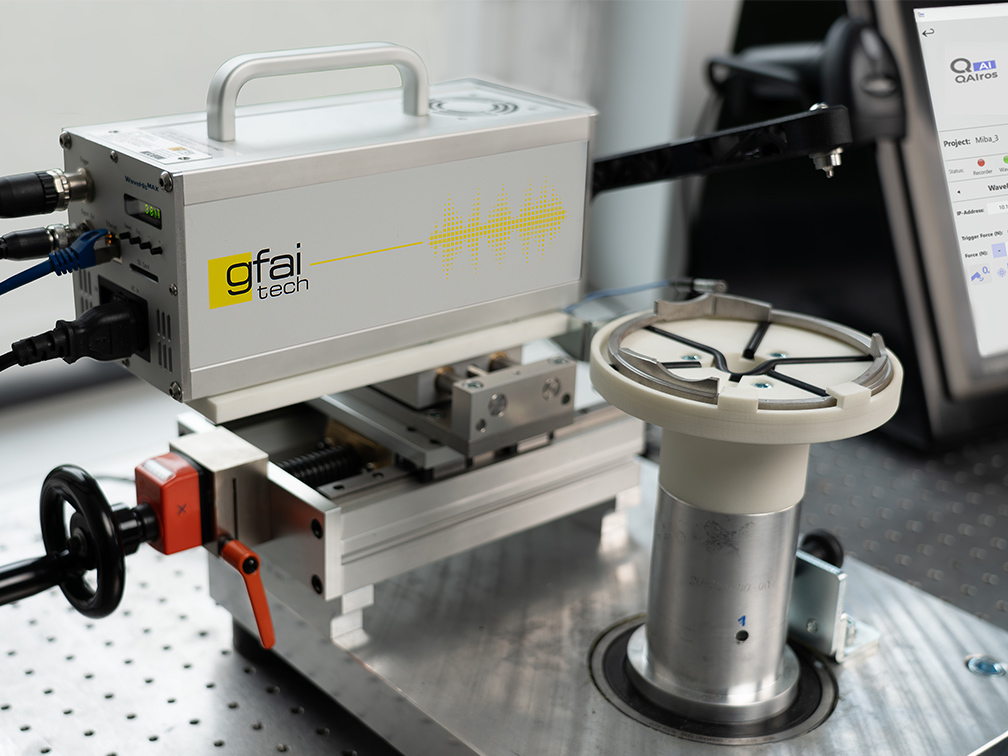

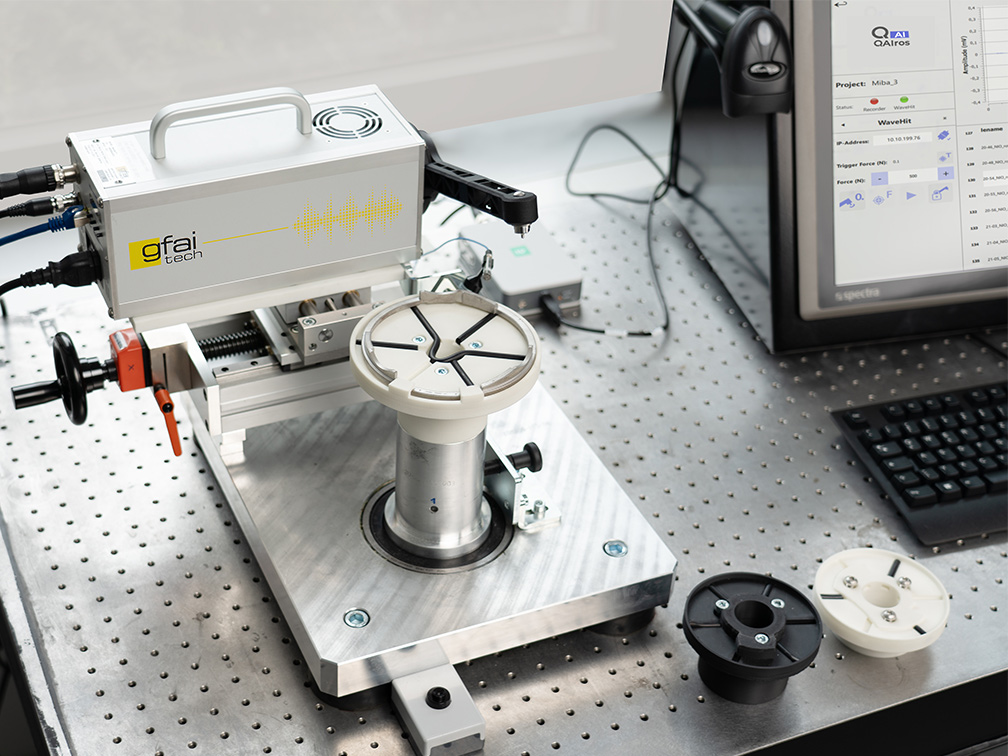

- Rotatable unit: This component is used to optimise the positioning of the test parts. It is able to rotate test parts by 120°, which enables three different test positions.

- Component-specific bearing: This is attached to the rotatable unit. It is customised using 3D printing technology to ensure an optimal fit and stability.

- Automatic impulse hammer WaveHitMAX, the orientation of which can be adjusted in the X and Y directions with a position indicator to ensure precise application of the test impacts.

- Microphone with variable orientation so that it can be optimally positioned to capture the sound response.

This hardware setup allows reproducible positioning and testing of test parts with diameters of up to 200 mm and a weight of up to 1 kg.

Software

Training

The AI models are trained in the training module of the software. It requires a data set consisting of good and reject parts of the specific test object which are provided by the customer. The test parts are excited at the appropriate points with the automatic impulse hammer WaveHitMAX while the microphone records the sound response. Using the data set the software trains the AI model automatically:

- Model training: The AI model analyses the recorded sound responses, identifies significant features to separate pass and fail parts and creates the model without manual intervention.

- Automatic validation: The model is validated by an internal division of the learning set, which increases accuracy and reliability.

- Flexible relearning: The model can be extended at any time by adding new data to integrate additional test parts and variations.

This approach does not require expert knowledge, as no manual adjustments such as threshold determinations or peak definitions are necessary.

Classifiation

The software's classification module enables new test parts to be tested using the trained model:

- Project file: A specific project file is created for each model, containing all relevant test settings (e.g. hammer force, position) to ensure consistent and reproducible measurements.

- Result documentation: The classification results are documented and can be seamlessly integrated into a database or exported in formats such as Excel and PowerPoint to facilitate further processing and analysis.