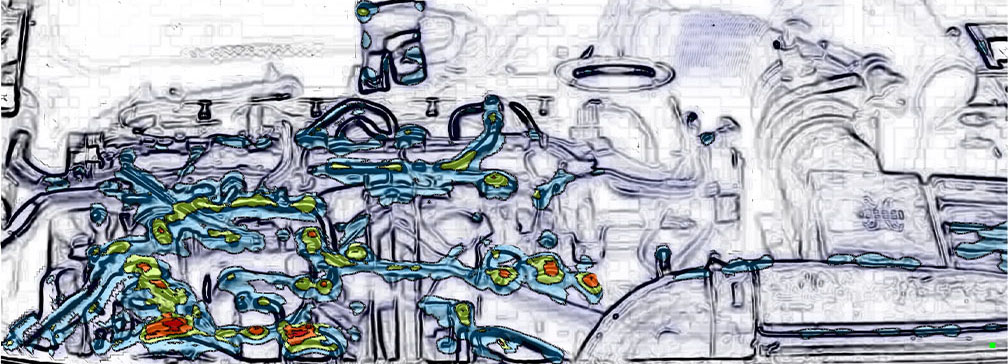

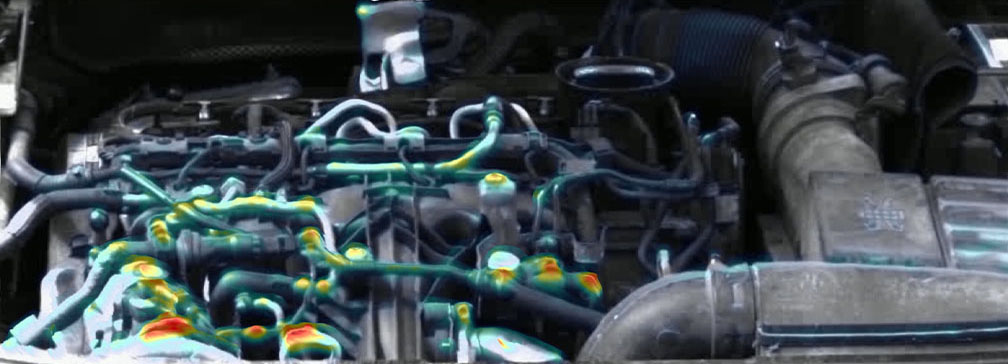

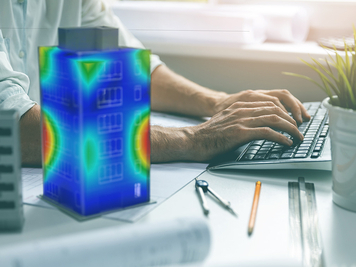

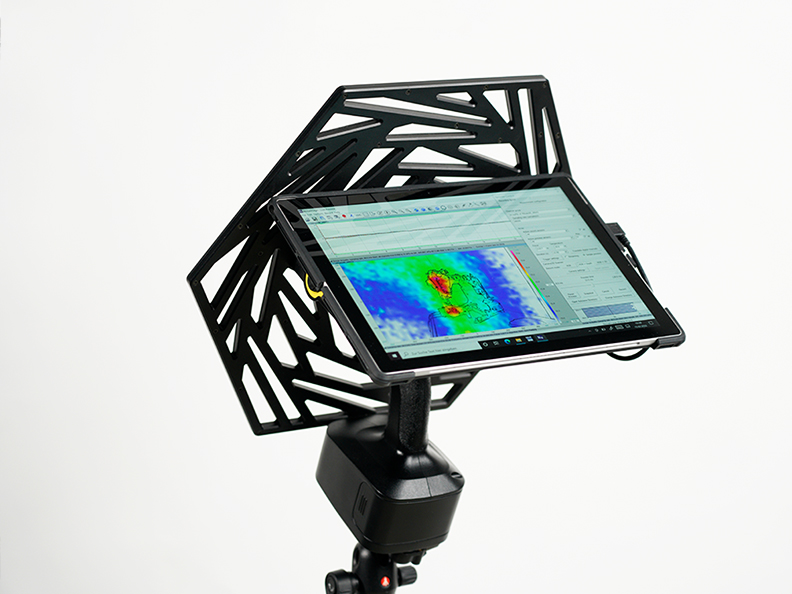

Immerse yourself in the possibilities of optical analysis with our advanced, non-contact and high-resolution vibration analysis solution WaveCam. We visualize a world in which vibrations are magnified and the invisible becomes visible. Learn why motion magnification is more than just a technique - it's a revolutionary way to understand and optimize vibration. Analyze your vibration data in the time, frequency and order domain to better understand machines, buildings and structures.

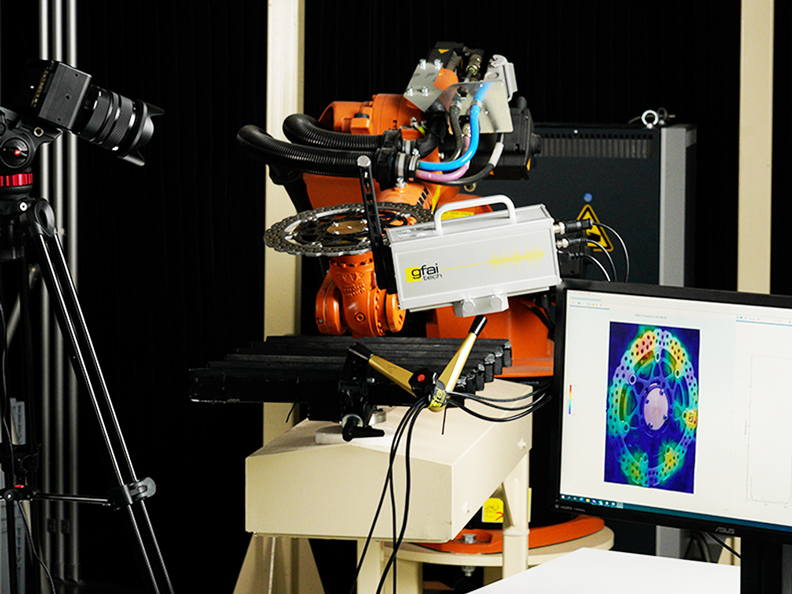

All you need to get started is a camera and our software to process the data. Save the time handling lots of cables and sensors, or setting and measuring single measurement locations consecutively. Each pixel acts as an individual sensor, enabling comprehensive monitoring of vibrations and motion tracking.

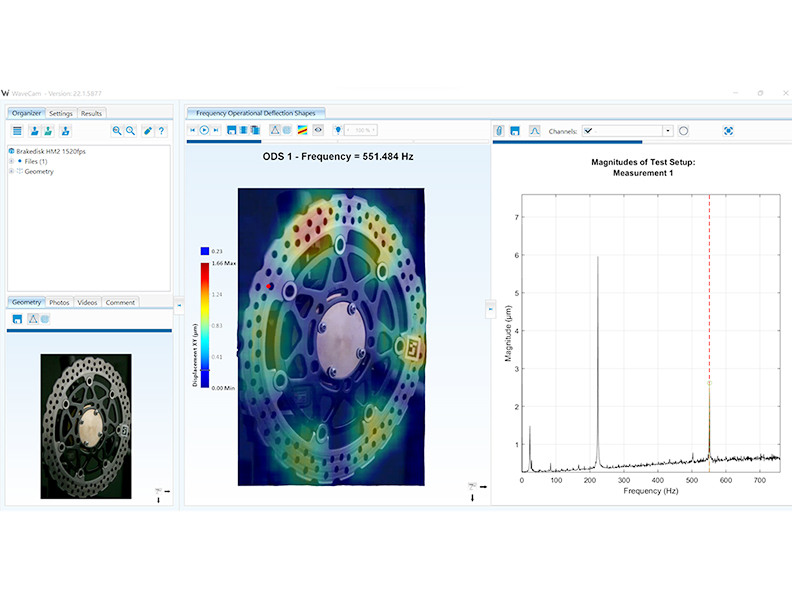

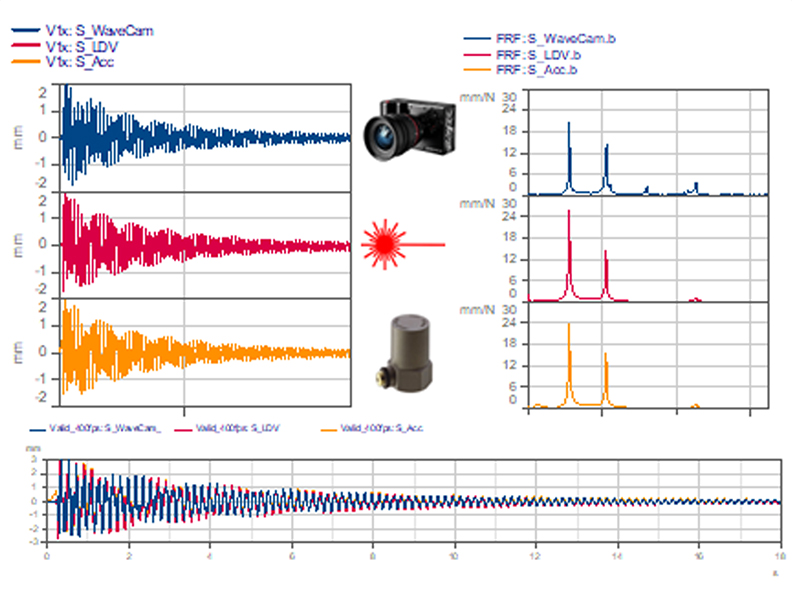

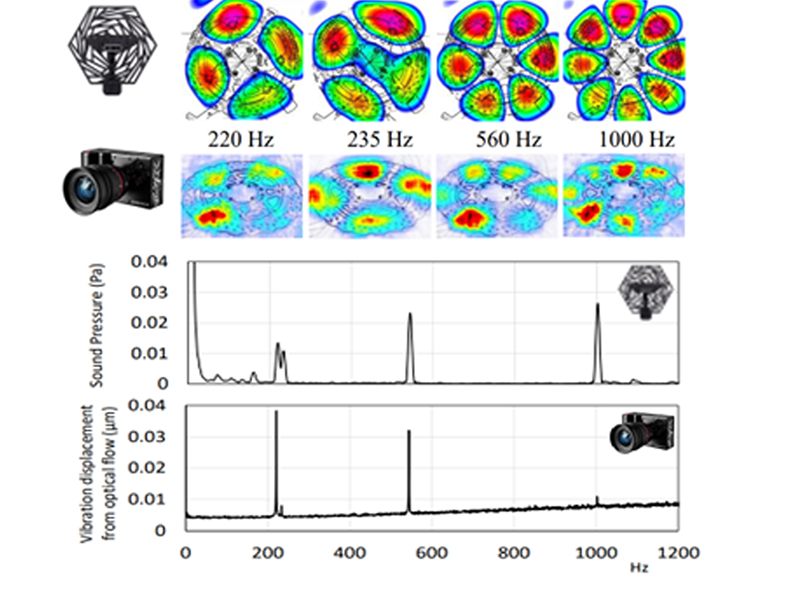

WaveCam allowing you to measure hundreds of thousands of positions simultaneously. Time waveforms and frequency data can be extracted for individual positions. Results were cross-validated with finite element analysis and conventional sensors like Doppler vibrometer (LDV), accelerometer as well as acoustic holography. Display deflection shapes of structures during operation, manual, ambient or automated excitation e. g. using the impulse hammer WaveHitMAX as well as transient events. Various options to display the data, facilitate interpretation and export vivid and conclusive results.

- Increase the productivity by reducing machine downtime

- Improve the life, safety, comfort and sound of the product

- Easy set up, shorter measuring times, no cable effort

- Simplification of maintenance, improved damage detection